We are Manufacturer, Supplier, Exporter of Furnace Elements, Coil Elements, Ribbon Heating Element, Radiant Tube Firebar Elements. Our setup is situated in Pune, Maharashtra, India. Our elements can be used in nearly all types of atmosphere conditions and can be placed in protective element tubes for indirect heating applications or those harsh environments that can cause element failure. Our elements are used in furnaces for annealing, brazing, non-ferrous melting & holding, salt bath, hardening, draw, temper and carbonizing applications. With a custom designed element, heat distribution can be specifically located to apply the heat where it can achieve the best results. Depending on the KW required, the elements will be made in either a large or small configuration. Mounting of these elements is simple, and can be horizontal or vertical, depending on the specific application.

Bayonet Specifications

Bayonet heating elements are custom designed for the voltage and wattage required satisfying the application. High performance bayonet elements are designed for high velocity convection furnace applications at temperatures approaching 1200oF or 1800oF with radiation heating, and maximum ratings per element.

Elements designed for higher temperatures or radiations heating require lower watt densities and thus lower maximum KW ratings per element. A Datta industry provides bayonet elements for furnaces manufactured by other furnace companies. Bayonet elements are also used to convert fuel-fired furnaces to electric heating.

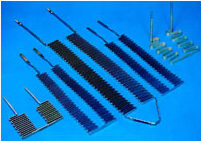

Coil Elements

By far the greatest number of heating element designs involve the use of round wire close-wound on an arbor or mandrel and then stretched to form a helix of at least twice the close-wound length. Proper, the next step in designing such elements is to choose a size of wire which will operate at the desired temperature and which can also be coiled to fit within the physical space limitations of the device. In most cases, some precedent will have been established as a basis for determining the proper wire size. Lacking prior experience.

Ribbon Heating Elements

Typical ribbon elements are often made consisting of two rows and are found suspended in refractory shaped in both ceiling, walls, and floors of small industrial high temperature furnaces. You will final the loops no longer than three to four inches, but the number of loops is unlimited. Some designs do have three layer terminal, which are punched for terminal connections, while others have round terminal leads, which are threaded for terminal connections, as per the picture. Every furnace manufacturer uses this style of element. The most popular electric heating element for a carburizing furnace.

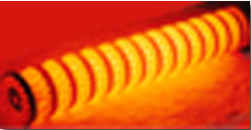

Radiant Tube Fire Elements

Vishwesh Heaters is leader in the manufacture of industrial heating elements, element, which With Firebar, conversion was easily accomplished by inserting the Firebar, a round heating element into the old radiant tube without any other alteration to the furnace. Firebar represented a tremendous break through in energy savings, economy of operation and longevity of equipment. Firebar is capable of liberating 85 BTUs of per square inch of pipe surface and sustaining temperatures as high as 1850_F